woodwork 11/12

COURSE OBJECTIVE:

The objective of this course is to further students’ hands-on skills in woodworking. Students will walk away with an understanding of taking wood from its raw form and being creative with it to form a variety of different types of project with I, the importance of safety while working in a shop and a set of hands-on skills with tools that can be used for the rest of their lives. This course is hands on!!

SAFETY

The following is a list of tools that involve students moving through a safety process that involves a demonstration, quiz, first use observation and ongoing supervision. The included links lead to documents that highlight the safety knowledge that all students must exhibit understanding of in order to use the tool.

Vcarve Tutorials

Vcarve Tutorials

The Push stick Tutorials are a very quick introduction to using Vcarve Software and how to use the CNC router to make a very quick project. All woodshops need push sticks to keep students safe and their fingers/hands away from blades.

Version 1

Version 2

Wood Theory

Theory will be given in the course that revolves around costing material and taking wood from a rough state to finished dimensions.

Dressing A Piece of Wood Procedure

Dressing a Piece of Wood

Calculating Materials

Bill Of Materials – Revised 2025

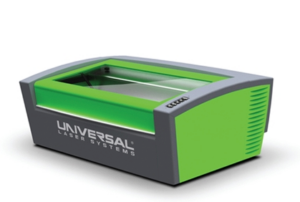

Laser Engraving and Inkscape Tutorials

Laser Engraving and Inkscape Tutorials

The Laser Engraver is a great addition to the Woodshop that opens up an endless array of projects and enhancements to projects that students can do.

Desk Plate/Sign/Fridge Magnet

(WOOD PROVIDED by Mr. Claassen)

Tutorials #1 – An introduction to Using Inkscape

Tutorials #2 – Text, Images & Tracing

Tutorial #3 – Going from Inkscape to the Laser Software

Tutorial #4 – Focusing and Cutting on the laser (No Video Yet)

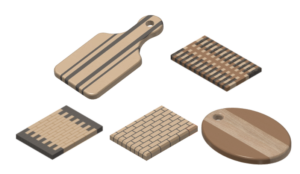

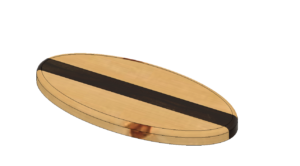

“Starter” Laminated Project

All students will start off with a simple laminated project to get back onto the tools & machines. Examples of this project include, but are not limited to; a set of coasters, cutting board, wall clock, cnc routed wall sign, charcuterie board, checker board, crib board. The incorporation of the laser and CNC Router are strongly encouraged!

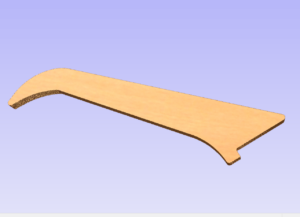

Autodesk Fusion 360 is industry standard 3D Modelling software. Students will use the software to create a three dimensional model of their project. Once created, 2 dimensional ‘working drawings’, or plans, will be generated which serve as a guide to the machining and assembling of the project.

Project Design Constraints:

- Project Planning – Your project will be modeled in 3D using Fusion 360

- Size

Overall Length & width – maximum 16″ (405 mm) in length and 12″ (300 mm) in width

Thickness – finished thickness of your cutting board shall be 3/4″ (19mm)

Single Board – no single board shall be wider than 3″ - # of Boards – your design must use a minimum of 4 pieces of wood to demonstrate your ability to laminate

- CNC/Laser – your design should incorporate the use of both the CNC router and the Laser engraver in an effort to enhance the finished product and demonstrate the ability to operate these tools.

- Working Drawing (plan) – from your completed model in Fusion, a dimensioned working drawing will be produced that will be used during construction of your project.

- Bill Of Materials – a Bill Of Materials must be completed before you start the project

- Wood Restrictions

Wood species must be chosen from those identified in class

Black Walnut/Purple Heart wood is only to be used for accent pieces ($$$)

Laminated project 2024 Procedure

Laminated Project Assessment 2024

Bill Of Materials – Revised 2025 (Download and Open)

Laminated Project Tutorial

These are the basics of Fusion to get you started drawing projects for woodwork. Follow this tutorial to design your laminated project.

Sketching and Starting a New Component – Part 2

Copying a piece and the Do’s and Don’ts

Joining components together – Part 4

Filleting and fixing a copy/joining – Part 5

3D to a 2D Working Drawing – Part 6